Air Mortar is a mortar in slurry form that incorporates foamed bubbles. It is composed of cement, clay-based fine aggregates, water, and a foaming agent. By adjusting the mix proportions, it can be produced at any required strength to suit various applications.

The FLOW-TAC Method is a construction method developed uniquely by TAC that utilizes FLOW-TAC Air Mortar. By incorporating Clay Sand containing montmorillonite, it significantly improves upon conventional clay-based Air Mortar, delivering superior fluidity, stability, and filling performance.

The independent bubbles mixed into FLOW-TAC Air Mortar are extremely fine and robust, providing high flow values and preventing material separation (no bleeding). As a result, the material achieves reliable filling of narrow voids while maintaining pumpability over distances exceeding 2,000 meters. Moreover, when used together with the auxiliary agent FLOW-TAC Aid, pumpability can extend to over 3,500 meters.

FLOW-TAC (flow value 300 mm)

With superplasticizer added

(flow value 400 mm)

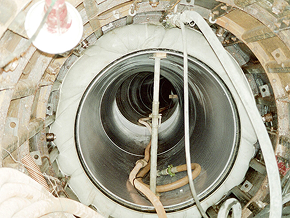

FLOW-TAC Air Mortar is suitable for a wide range of applications, including backfill grouting associated with pipe installation in shield tunnels, void filling in mountain tunnels, coastal structures, and building foundations.

|

Uniaxial Compressive Strength (28-Day Strength) |

Blast Furnace Cement | TAC-α | TAC-Foam H | Water | Air Content | Density |

|---|---|---|---|---|---|---|

| 0.1–0.2 N/mm² | 200 kg | 30 kg | 0.8 kg | 522 L | 40% | 0.75 |

| 0.5–1.0 N/mm² | 250 kg | 30 kg | 0.8 kg | 506 L | 40% | 0.79 |

| 1.0 N/mm² | 300 kg | 25 kg | 0.7 kg | 541 L | 35% | 0.87 |

| 1.5 N/mm² | 350 kg | 25 kg | 0.7 kg | 525 L | 35% | 0.90 |

| 2.0 N/mm² | 400 kg | 25 kg | 0.4 kg | 658 L | 20% | 1.08 |

This section introduces the mechanism of FLOW-TAC and examples of its application.

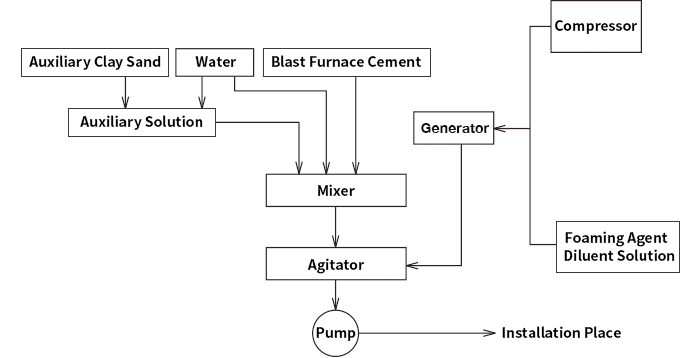

A premixed auxiliary material solution is prepared in advance by mixing and dissolving bentonite or Clay Sand used as auxiliary agents, allowing them to fully swell. This pre-mixing system for auxiliary materials is an essential process to prevent foam collapse.

① Add the prepared auxiliary material solution and the specified amount of water into the mixer, then add cement while agitating.

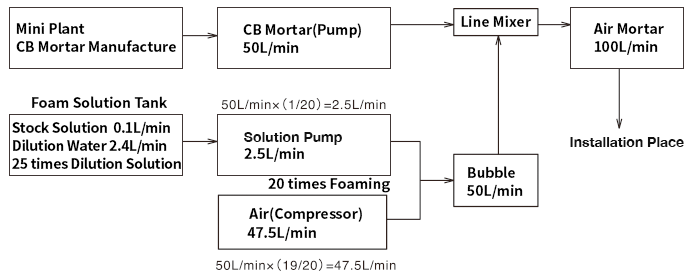

② Compressed air generated by a compressor is forcibly mixed with the foaming agent, producing fine and uniform foam—similar in texture to shaving cream—through a foam-generating tube.

③ Introduce the foam into the freshly mixed mortar and agitate.

④ This completes the production of FLOW-TAC Air Mortar.

⑤ For long-distance pumping, FLOW-TAC Aid may be added as needed to further enhance fluidity.

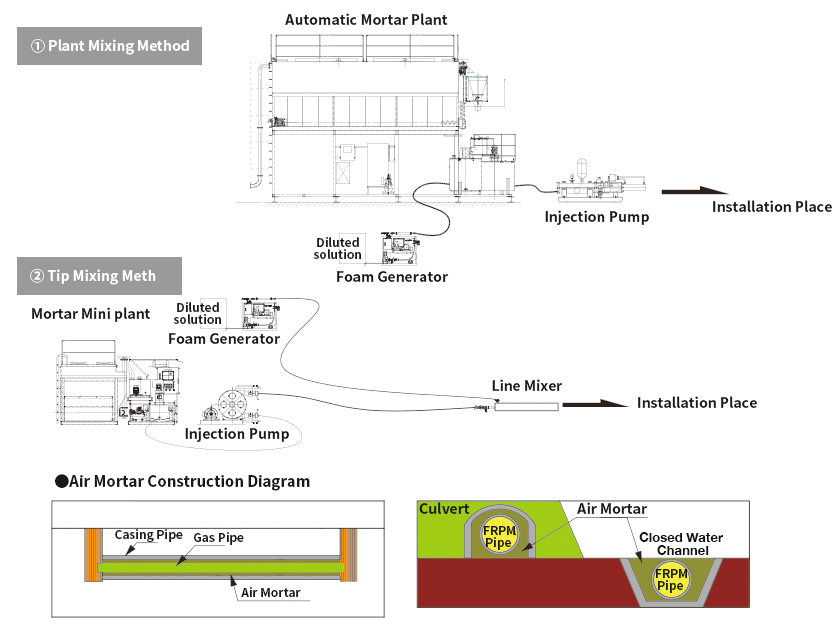

Compact Mini Plant for Limited Space

W Plant for Large-Volume Construction

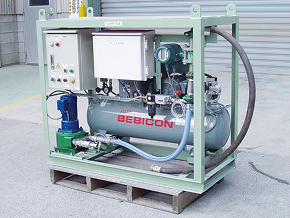

Foaming Unit

Foaming Condition

Before Air Mortar Placement

During Air Mortar Placement

After Air Mortar Placement

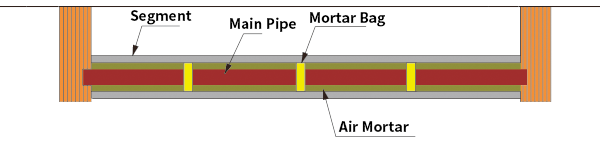

In pipe installation work, traditional partitioning for backfill Air Mortar injection has relied on bricks or mortar. However, these methods posed challenges, including long working hours and difficulty in ensuring sufficient strength.

The FLOW Mortar Bag developed by TAC features a large, bladder-like structure that is attached to the piping at the designated partition position. By injecting backfill mortar—either as is or with added plasticity modifiers—into the bag, partitioning can be performed easily and efficiently.

TEL:+81-869-84-2069

Phone Hours::Weekdays 9:00–17:00 (JST)

FAX:+81-869-84-3288