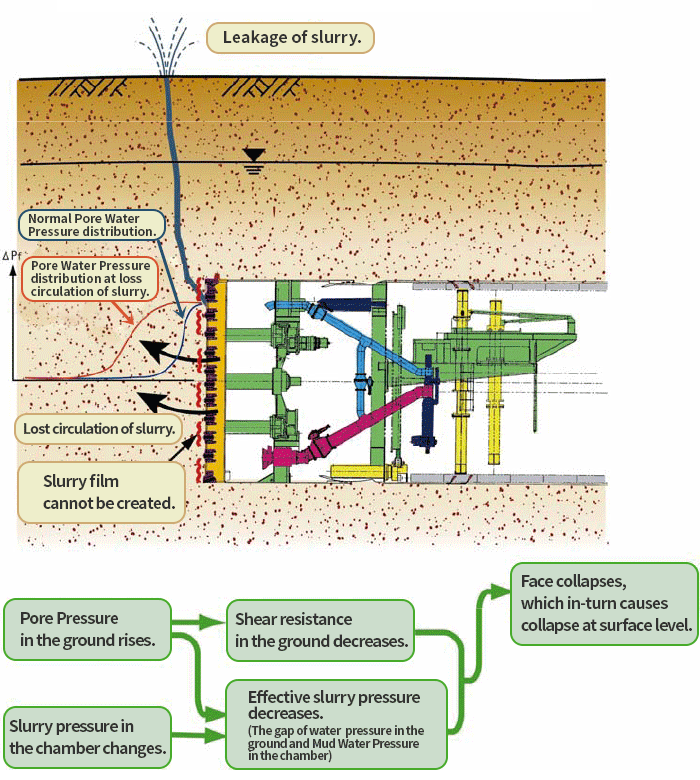

In the slurry shield method, a low-permeability mud film is formed on the tunnel face, and slurry pressure—equivalent to the surrounding earth and water pressure—is applied within the chamber to maintain face stability.

However, in gravelly sand layers, or when slurry deteriorates or slurry pressure fluctuates, the formation of the mud film may be delayed or insufficient. In such cases, a "slurry loss phenomenon" can occur in which slurry rapidly infiltrates the ground at the tunnel face. As a result, effective slurry pressure decreases, increasing the risk of face collapse or ground settlement.

To prevent such situations, TAC ensures thorough quality control of slurry and provides Slurry Material tailored to specific applications.

Mechanism of Face Collapse Caused by Slurry Loss

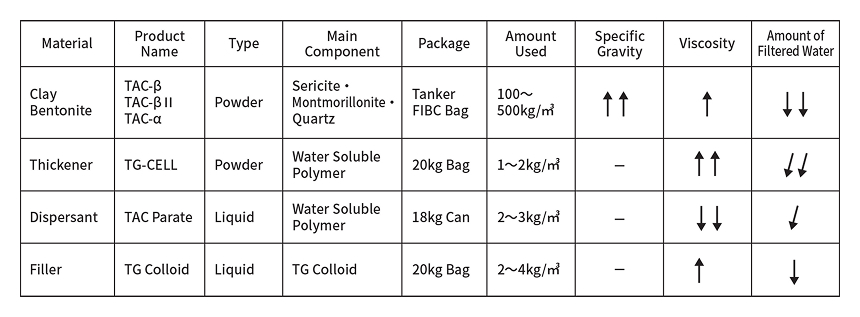

Here we introduce the types and characteristics of Slurry Material that can be selected according to construction conditions.

| Classification | Main Purpose / Effect | Features of TAC Products |

|---|---|---|

| Bentonite / Clay | Prevents collapse of the excavation face by forming a mud film. Clay also serves as a filling material for sand–gravel ground and as a weighting agent. |

TAC's Clay Sand combines the characteristics of both bentonite and clay. With favorable particle-size distribution, it can be selected according to ground conditions. |

| Viscosity Enhancer | Prevents slurry separation and sedimentation. Enhances the aggregating effect of bentonite and maintains viscosity. |

Compared with general products, TAC materials offer higher viscosity and greater solubility, making them easier to manage. |

| Dispersant | In excavation of improved ground or clayey ground, reduces viscosity to decrease waste slurry volume. Enhances reusability. |

TAC has extensive experience in supplying additives for clayey soils, suitable for slurry pressure shield applications. |

| Sealing Material | Prevents slurry loss in sand–gravel layers. | Uses superabsorbent polymer capable of swelling in slurry. Adjusted to less than 74 microns to prevent clogging and ensure reusability. |

To ensure stable excavation, the quality of slurry properties is carefully monitored and controlled.

TEL:+81-869-84-2069

Phone Hours::Weekdays 9:00–17:00 (JST)

FAX:+81-869-84-3288