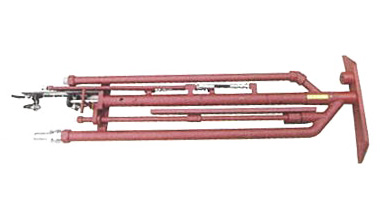

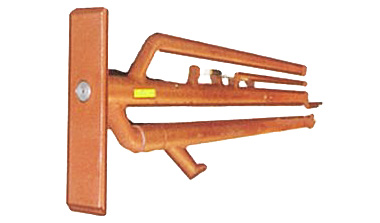

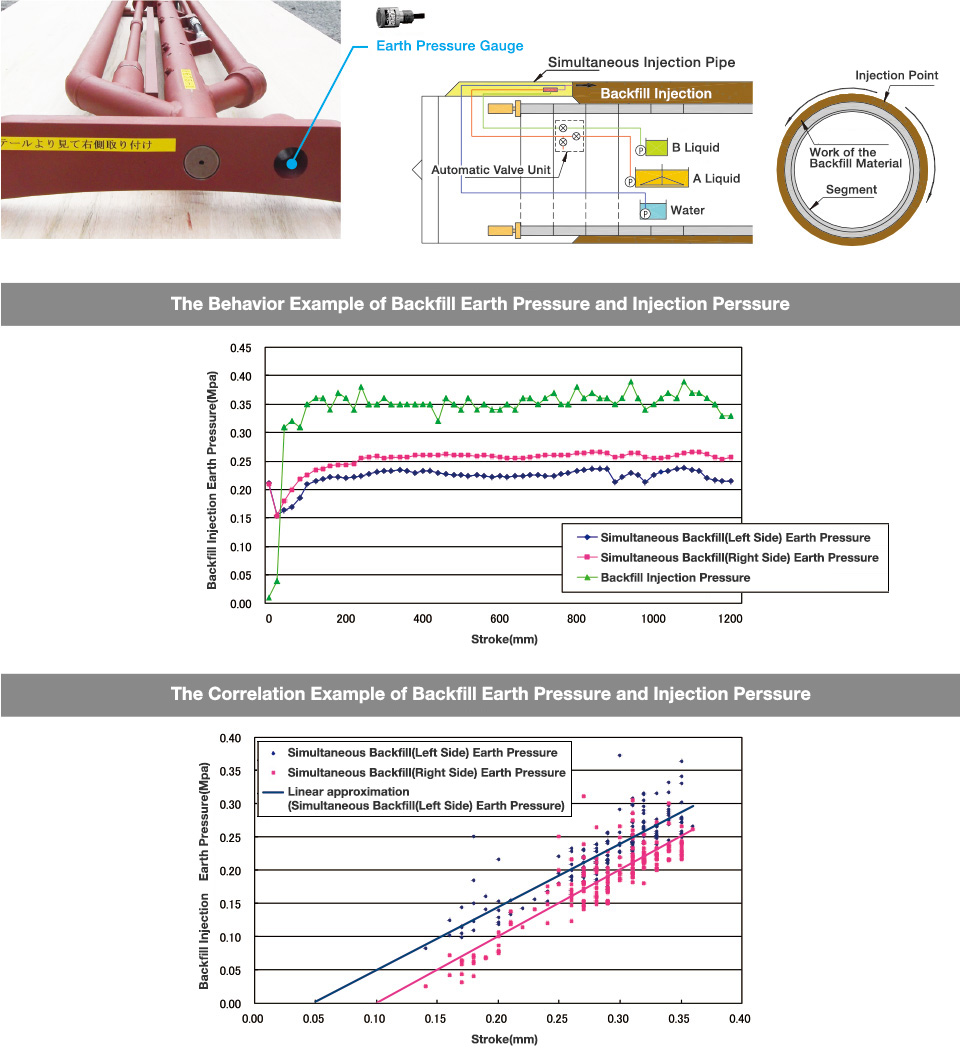

Simultaneous Injection Pipe

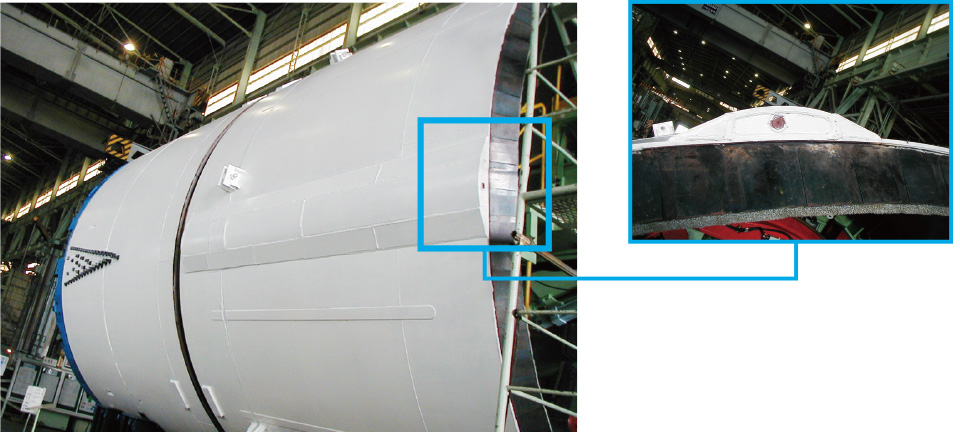

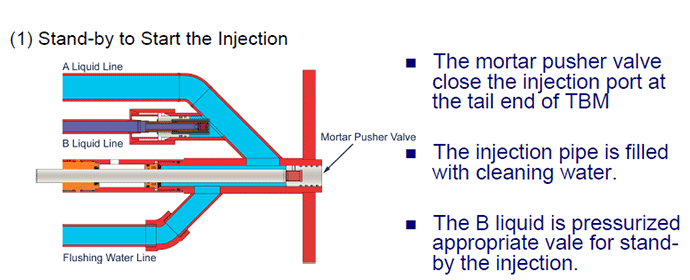

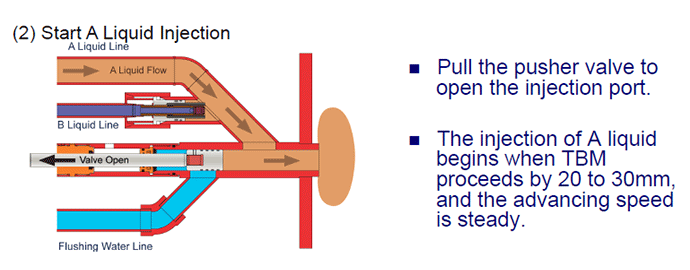

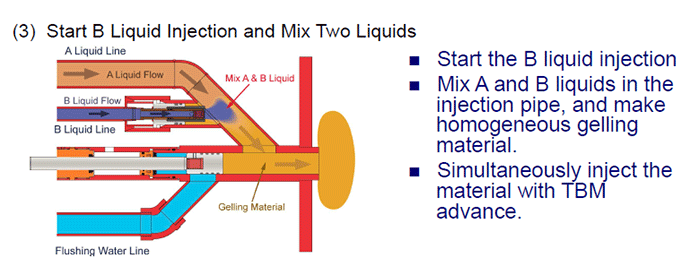

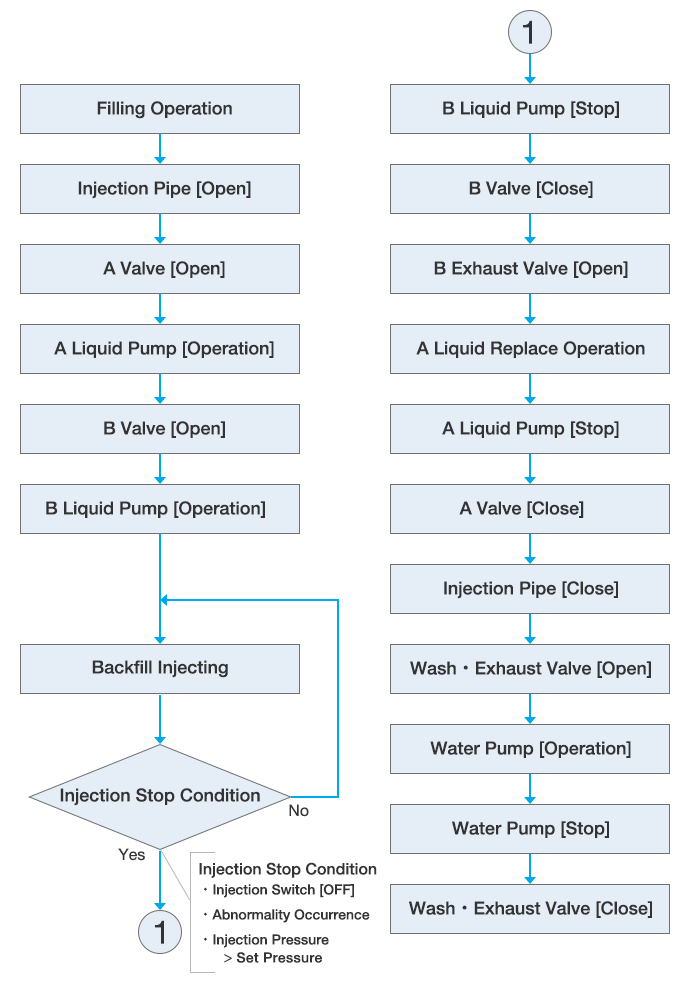

1. The simultaneous injection method for backfill grout injection involves the installation of an injection pipe at the upper part of the shielding machine and then injecting backfill grout at the same time as the shield machine drills and creates the tail void.

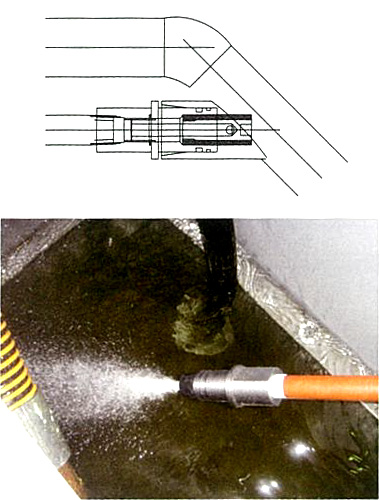

Using simultaneous injection a mixing nozzle blends two liquids at the tip of the injection pipe. This allows injection to occur in the same way as segmental injection, therefore dramatically reducing problems caused by blockages.

Simultaneous Injection Pipe: Tip Mixing Type

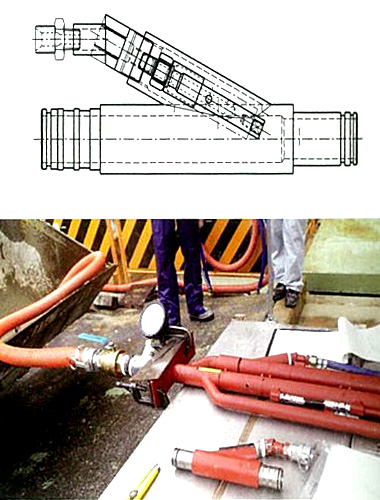

Simultaneous Injection System

Simultaneous Injection Pressure Measurement

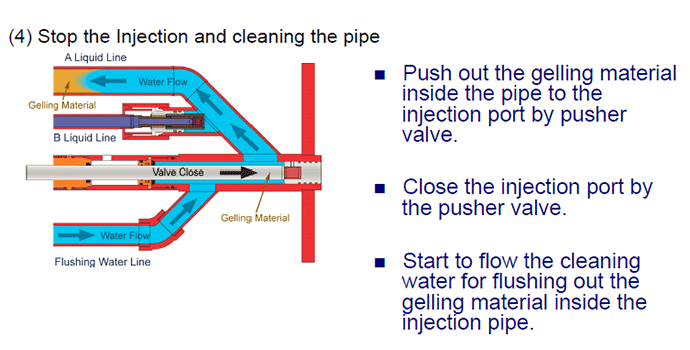

Injector Maintenance

The simultaneous injection pipe indicator for needing maintenance is the increase of back pressure in B liquid pressure as well as back pressure in the washing water pressure. It is necessary to regularly replace tube rubber. In addition, as mortar “cholesterol” can sometimes adhere to the inner surface of the injection tube, it is best to circulate in the tube with TAC clean or to clean it with a can tool.