Backfill Grout Injection Materials

Materials Used

| Material | Item Name | Packing | Specific Gravity | Intended Use |

|---|---|---|---|---|

| Hardening Material | TAC-ment | Tanker | 3.15 |

|

| Additional Material | TAC-α TAC-βⅡ |

Tanker | 2.6 |

|

| Foaming Agent | TAC-2 | 19kg/can | 1.0 |

|

| Stabilizing Agent | TAC-Re | 20kg/can | 1.27 |

|

| Plasticity Modifier | TAC-3G | Tanker | 1.37 |

|

| Material | Item Name | Packing | Specific Gravity | Intended Use |

|---|---|---|---|---|

| Gelling Agent | TAC-GEL | 25kg/bag | 1.00 |

|

Standard formulation examples.

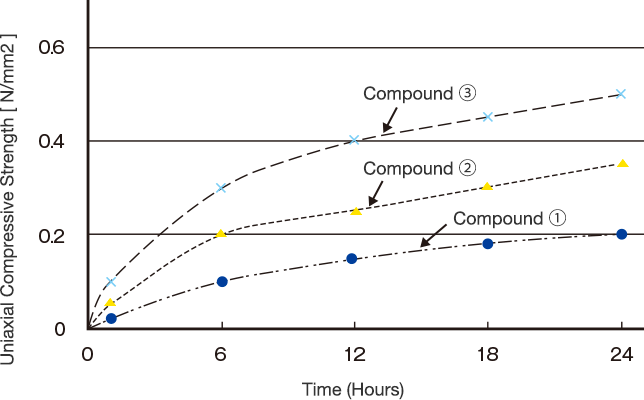

| Region | 1㎡ Compound | Uniaxial Compressive Strength (N/mm2) |

|||||||

| Liquid A | Liquid B | ||||||||

| Hardening Material | Aux Material | Foaming Agent | Stabilising Agent | Water | Air Volume | Plasticizing Agent | |||

| TAC-ment | TAC-α | TAC-2 | TAC-Re | Fresh Water | TAC-3G | After 1 hour | |||

| Kansai / Chugoku / Shikoku region (Okayama produced TAC-α) |

① | 230kg | 30kg | 0.5kg | 2.3kg | 720L | 143L | 50L | 0.03 |

| ② | 250kg | 30kg | 0.5kg | 2.5kg | 710L | 142L | 55L | 0.05 | |

| ③ | 270kg | 30kg | 0.5kg | 2.7kg | 699L | 141L | 60L | 0.10 | |

| Eastern Japan (Yamagata produced TAC-α) |

① | 230kg | 20kg | 0.5kg | 2.3kg | 724L | 143L | 50L | 0.03 |

| ② | 250kg | 20kg | 0.5kg | 2.5kg | 714L | 142L | 55L | 0.05 | |

| ③ | 270kg | 20kg | 0.5kg | 2.7kg | 703L | 141L | 60L | 0.10 | |

| Tokai / Hokuriku (Gifu produced TAC-α) |

① | 230kg | 20kg | 0.5kg | 2.3kg | 724L | 143L | 50L | 0.03 |

| ② | 250kg | 20kg | 0.5kg | 2.5kg | 713L | 142L | 55L | 0.05 | |

| ③ | 270kg | 20kg | 0.5kg | 2.7kg | 703L | 141L | 60L | 0.10 | |

| Kyushu (Kyushu produced TAC-α) |

① | 230kg | 33kg | 0.5kg | 2.3kg | 719L | 143L | 50L | 0.03 |

| ② | 250kg | 33kg | 0.5kg | 2.5kg | 708L | 142L | 55L | 0.05 | |

| ③ | 270kg | 33kg | 0.5kg | 2.7kg | 698L | 141L | 60L | 0.10 | |